Kiln operation:

1

2

We will now consider each step of this process to identify the significant details of their

execution.

Raw Clay Handling

The quality of finished tiles rests greatly on selection and ageing of raw clay (raw clay being

that which is just dug from a mine). As has been mentioned, it is likely that you will have to

blend two clays (possibly more) to obtain a suitable clay for tile production. These clays may

be blended at this stage or after the ageing. The clav must then age for at least one year,

more typically two years. During this ageing the clay should be completely exposed to the

elements (without cover). Through the natural course of wetting and drying the clots and

lumps of clay break down, making the clay workable and consistent. This ageing action is

absolutely necessary to obtain a high quality finished tile.

The clay storage site is easily managed by continually dumping on the top of the pile, and

removing clay from the side of the pile. A front loading tractor is very helpful in this operation

(blending and loading), but it can also be managed by labourers with ordinary farming hoes. A

hydraulically lifting tractor trailer for labour free unloading of clay is almost essential, and

certainly pays for itself in saved labour very quickly.

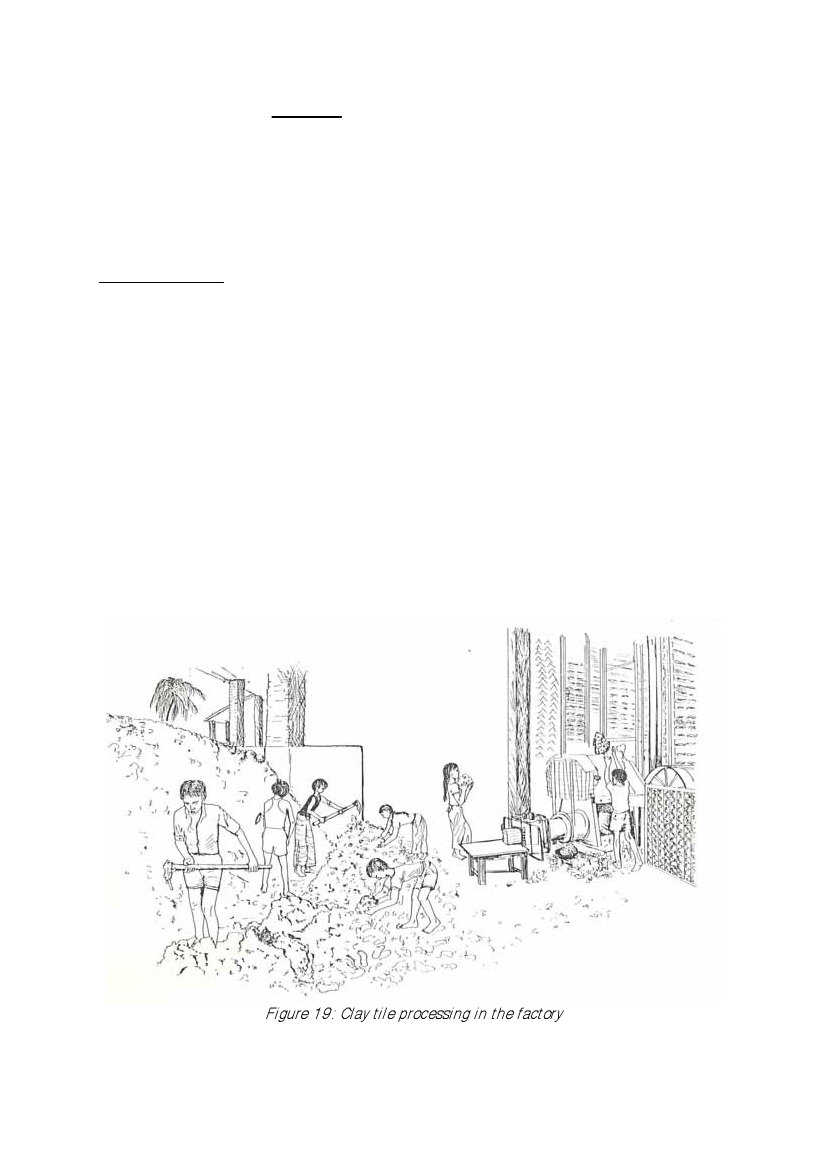

Figure 19: Clay tile processing in the factory